ORCCO's SOP in Office Chair Quality

New Product Development Quality Control

Ensures the practicability and reliability of products with rational design and customer demands at the beginning of products development. Tests every sample and detects every flaw in the design stage prior to mass production.

(1) Sample Production

R&D team produce the first sample after the molds of new product

were completed. QC team review the functionality and detail of the

sample, mention the suggestion of improvement.

(2) Mold Sample Test

Test the samples under BIFMA standard and DIN EN1335 standard,verify the functionality and reliability of samples in full depth.

(3) Trail production

Make a trail production of the new products, Review and solve all problems found in the period of production.

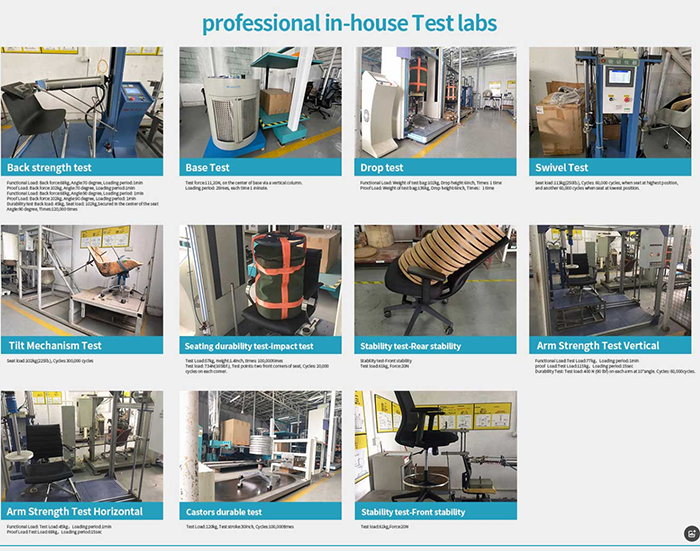

(4) professional in-house Test labs

The test lab is supporting a complete set of BIFMA testing equipment and methods.

Mass Production Quality Control

Reviews and analyzes the data collected while monitoring production to improve quality, increase yield and minimize postponement incidents.

Incoming Quality Control

We not only select about distributors, but also about incoming materials.Vinyl/leather/fabric/mesh-Fire proof test,abrasion test

Plywood- EPATSCA TITLEVI Certificate for approving Metal Components--Pass the Salt Water Spray Test to avoid corrosion Gas Spring-Pass the strength test to approve the performance Carton--200lbs weight rating test

In-Process Quality Control

Inspections will be done in various forms during in-process production。

Implementing 6S management .Each step follows a complete SOP standard with IPQC inspections, guaranteeing high standards in plywood processing, sewing, upholstering, and assembly.

Finished Quality Control

Before warehousing, each product and its packaging undergo strict inspection, followed by final quality control based on AQL standards. The process includes checking assembly quality, measurement accuracy, strength testing, and functionality to ensure compliance with factory standards.

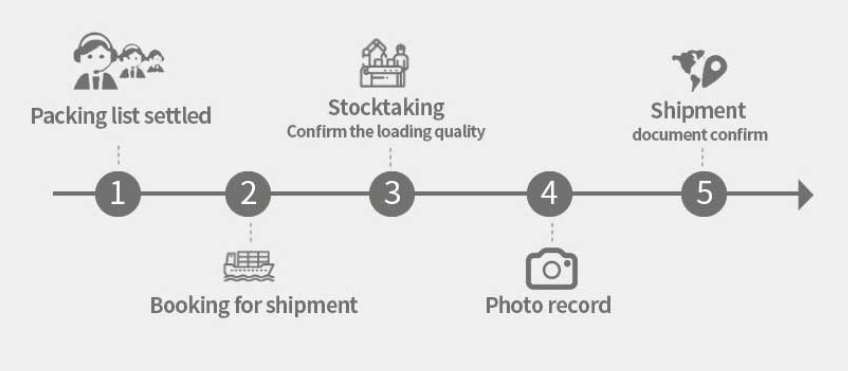

Outgoing Quality Control

The last inspection before shipment

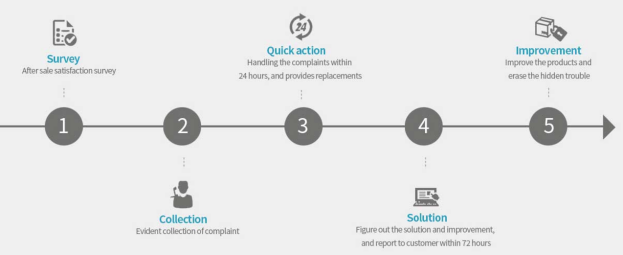

After Sales Quality Control

We endeavour to provide high quality service, high accuracy and high efficiency solution to the clients.